Society is dependent on the metals and minerals produced by mines, and the employment that the mines and mineral processing provide. However, at the same time the activities can result in environmental impacts such as the release of acidic leachate with heavy metals into waterways. SEESIMA project, funded by Kolarctic CBC, aims to raise awareness of technological solutions to environmental impacts of mining activities, in order to reduce environmental impacts and improve economic returns.

Modern society is dependent on the products from mines. A mobile phone contains more than 60 different minerals produced by mining. However, consumers are largely unaware of the origins of the products that they buy, and mining often features in the media only through attention to negative environmental effects. In project SEESIMA (Supporting Environmental Economic and Social Impacts of Mining Activity) we aim to make information about mining activities in our region more readily available.

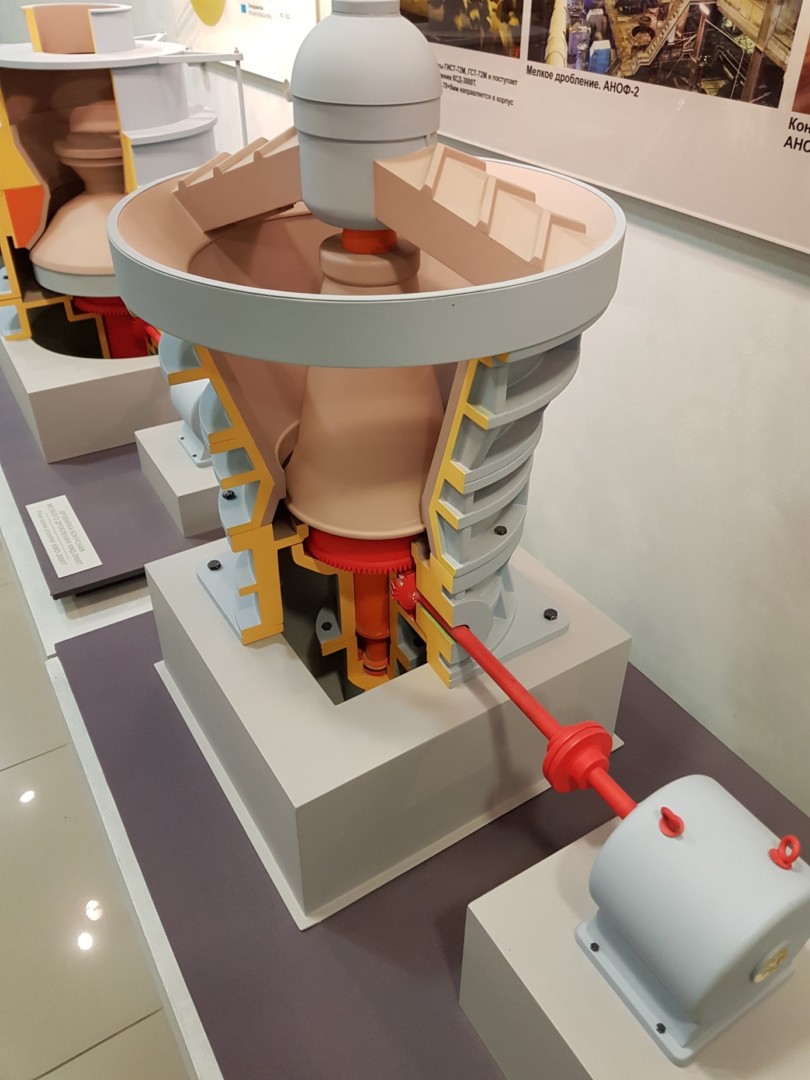

The mining industry consumes 10% of the world’s energy[1], of which a large part is used for reducing the size of the rocks to allow the separation of the valuable components from the waste rock. Reducing the rock to smaller sizes increases the energy consumption and can give problems in the later disposal of the waste rock. If the rock pieces are too large the separation of the valuable components can have a lower efficiency, reducing the economic result.

The process of reducing the size of the rock can be likened to chewing your food, and there are ways of making it more efficient.

There are many processes that you use to improve the efficiency of eating. You cut up the food before putting it in your mouth, you use your jaw and tongue to move the food around in your mouth, and use your teeth to bite or grind the food. If the food is dry you might add some drink to help the process. You have learn to chew the food well before swallowing for further processing in your stomach – or risk choking or getting stomach ache. And the amount of food you can chew is limited by the size of your mouth and the effort you put into chewing. Many of these processes also occur on the mining industry, just that different machines are used to make the processing.

In project SEESIMA studies have been made of ways to improve the energy efficiency of grinding of rocks and separating the valuable components. Two approaches were made. The Mining Institute at the Kola Science Centre has examined different combinations of size reduction and separation processes, including dividing these operations into multiple stages. Testing at pilot plant scale indicated that by optimising the ways the different operations were combined the amount of energy could be reduced by 10-15 % while achieving the same efficiency of separation.

Similar to chewing dry food, it is common to use water to help transport the rocks in the machinery, but it is desirable to use as little water as possible. Some mines use a size reduction process without water, termed «Dry Grinding». This avoids the need to treat the waste water produced, but typically uses more energy than wet grinding. At Luleå Technical University the researchers have examined the effect of additives that made the size reduction and separation more efficient for Dry Grinding. The researchers at LTU have show that the energy used for Dry Grinding can be reduced by as much as 30%. Further works remains to determine what energy savings are possible if these results were implemented in industry.

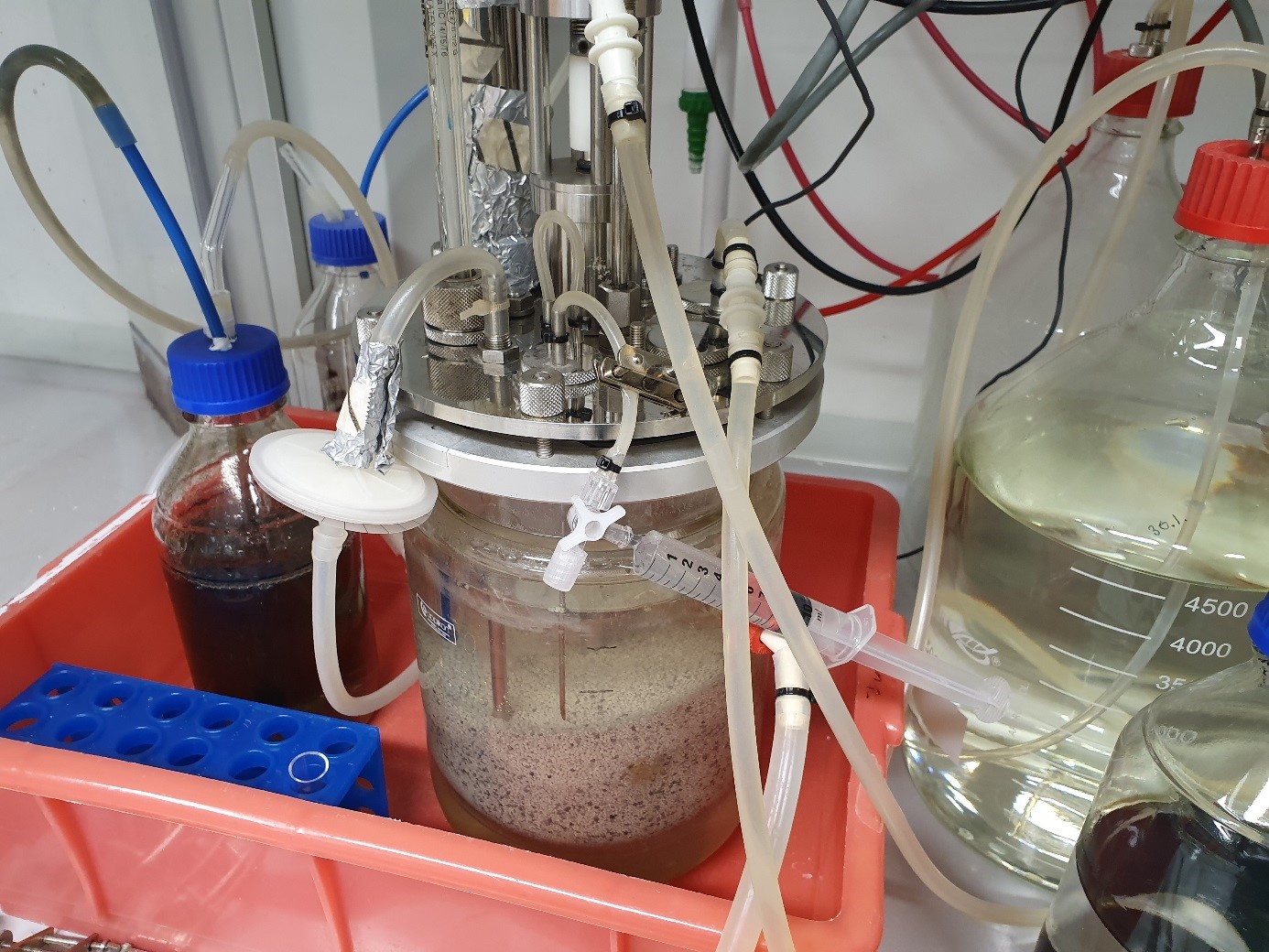

Laboratory studies investigating how microbes can be used to produce hydrogen sulphide that helps to remove heavy metal from wastewater. The experiments are made at low temperatures relevant to the Kolarctic region.

The waste rock produced by mines has usually been disposed of in landfills. The reduction of the size of the particles can result in chemicals and heavy metals being released from the landfill into waterways. Another workpackage of the SEESIMA project is investigating different technologies for cleaning the mine waste water, using biologically-based sorbents (acting like sponges) or microbes. Another problem with mine waste water can be the high concentrations of sulphate ions. Microbes can be used to convert the sulphate to sulphides which can precipitate metals from mine waste water. This cleaning can reduce the impact of the waste water released to the environment.

Another work package of the SEESIMA project is investigating ways the waste rock can be used for other products – such as for building material, or to extract other valuable products.

More details about the Kolarctic SEESIMA project can be found at the webpage www.seesima.eu.

Reindeer inspecting an experimental set-up where mine waste water is being cleaned. (Photo: Tiina Leiviskä, from collaboration with Interreg Nord VanProd project)

[1] https://www.theworldcounts.com/challenges/planet-earth/mining/energy-use-in-the-mining-industry/story